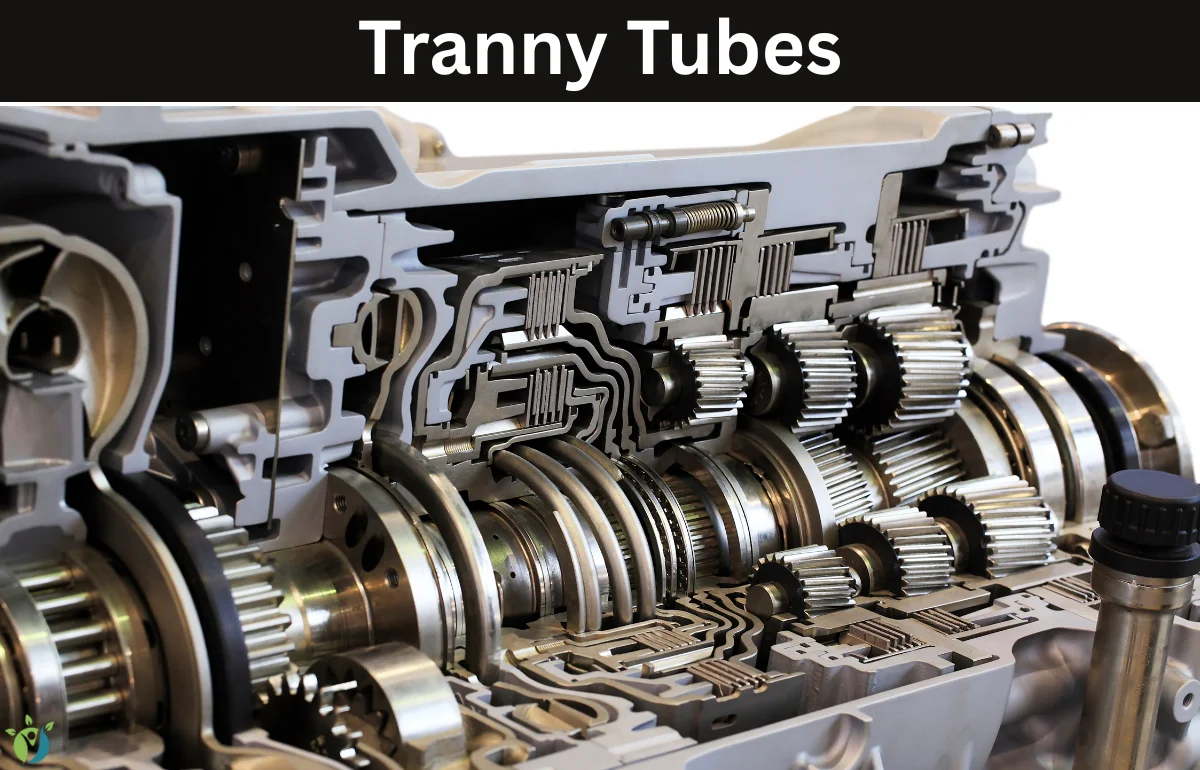

When it comes to maintaining your vehicle’s transmission system, one essential yet often overlooked component is the tranny tube. Tranny tubes, also known as transmission lines, play a critical role in the smooth operation of your car, truck, or SUV. These specialized tubes are responsible for transferring transmission fluid throughout the system, helping to keep everything running at peak performance. In this article, we will delve into what tranny tubes are, their importance in preventing overheating, the different types available, and how to install, maintain, and replace them.

What Are Tranny Tubes?

At the most basic level, tranny tubes are tubes that carry transmission fluid through your vehicle’s transmission system. Transmission fluid is crucial for lubricating, cooling, and cleaning various components within the transmission. Tranny tubes connect the transmission to other vital parts, such as the radiator and torque converter, ensuring that fluid flows efficiently, which helps prevent transmission failure and overheating.

The Role of Tranny Tubes in Fluid Transfer

The primary function of tranny tubes is to transport automatic transmission fluid (ATF) throughout your vehicle’s transmission system. This fluid plays a vital role in keeping the transmission components well-lubricated, reducing friction, and cooling the system. Without proper fluid circulation, your transmission can quickly overheat, leading to costly damage.

Tranny tubes carry the ATF to and from various components, including the transmission, radiator, and torque converter. By transferring the fluid to the radiator, these tubes help cool down the fluid, which can heat up quickly due to the friction inside the transmission. This cycle of fluid cooling is vital to maintain safe operating temperatures and prevent overheating, a leading cause of transmission failure.

Why Tranny Tubes Are Important for Preventing Overheating

One of the critical functions of tranny tubes is their ability to prevent your transmission from overheating. The transmission system generates a lot of heat as it operates, and if the fluid gets too hot, it can cause permanent damage to the transmission. Tranny tubes help mitigate this by carrying the heated fluid to the radiator, where it is cooled before returning to the transmission system.

Without efficient fluid transfer and cooling, your transmission system could quickly become compromised. Overheating can lead to burned-out clutches, broken gears, and a complete failure of the transmission system, all of which can be costly to repair or replace.

The Durability of Tranny Tubes: What Are They Made Of?

Given their vital role in your vehicle’s transmission system, tranny tubes need to be durable and resistant to heat, pressure, and corrosion. Over time, these tubes can wear out due to the harsh conditions inside the transmission system, so understanding the materials they are made from is essential.

Tranny tubes are made from various materials, including:

Copper Tranny Tubes

Copper is one of the most durable materials for tranny tubes, offering excellent conductivity and corrosion resistance. Copper tubes are ideal for applications that require high conductivity, and they tend to last longer than other materials. However, they can be more expensive compared to other options.

Aluminum Tranny Tubes

Aluminum is lightweight, corrosion-resistant, and affordable, making it a popular choice for tranny tubes. However, aluminum is not as conductive as copper and is more prone to damage under high pressure or extreme temperatures. Still, it’s a good option for those looking for a cost-effective material that’s easy to install and replace.

Steel Tranny Tubes

Steel is incredibly durable and can withstand high pressures, making it suitable for heavy-duty applications. While steel is more resistant to damage and corrosion than aluminum, it requires coating or treatment to prevent rusting. Steel tranny tubes are typically heavier and more difficult to install but offer long-lasting performance.

Plastic Tranny Tubes

Plastic materials like PVC, nylon, and polyethylene are used for tranny tubes when electrical conductivity is not a concern. Plastic tubes are affordable and lightweight, making them easy to install and maintain. However, they are less heat-resistant and have a lower pressure tolerance compared to metal options.

How to Install Tranny Tubes: A Step-by-Step Guide

Proper installation of tranny tubes is crucial for ensuring that your vehicle’s transmission system functions correctly. Follow this simple, step-by-step guide to install your new tranny tubes:

- Locate the Transmission Cooler Lines: Begin by identifying the transmission cooler lines under your vehicle. These are the lines that connect to your radiator. Make sure your vehicle is turned off and that it is cool to the touch before proceeding.

- Disconnect the Old Tranny Tubes: Use a wrench to disconnect the old tranny tubes from the radiator and transmission. Be prepared for some fluid to spill, so have a catch pan nearby to avoid a mess.

- Install the New Tubes: Once the old tubes are removed, align the new tubes and connect them to the appropriate parts. Tighten the connections carefully to avoid any leaks.

- Check for Leaks: After installation, start your vehicle and inspect the new tubes for any leaks. Tighten the connections if necessary.

- Add Transmission Fluid: Ensure that your vehicle has the appropriate level of transmission fluid. If necessary, top off the fluid to the correct level.

- Test Drive: Take your vehicle for a short test drive to ensure everything is working properly. Pay attention to any unusual sounds or issues with shifting.

Maintenance and Replacement of Tranny Tubes

Like all vehicle components, tranny tubes require regular maintenance to ensure optimal performance. Follow these tips to extend the lifespan of your tranny tubes:

Regular Inspections

Inspect your tranny tubes at least once every 6 months for signs of wear or damage. Look for cracks, leaks, or fraying, especially around the connection points. Catching problems in advance can save you from costly fixes in the future.

Fluid Flushing

Perform a transmission fluid flush every 20,000 to 30,000 miles to keep your system clean and running efficiently. Flushing removes debris and contaminants that may have accumulated in the fluid, ensuring smooth operation and preventing damage to the tubes.

Replacement of Worn Tranny Tubes

If your tranny tubes show signs of significant wear or damage, it’s crucial to replace them as soon as possible. Depending on the material and usage, they can last anywhere from 50,000 to 100,000 miles. Regular inspections will help you determine when it’s time to replace them.

Conclusion: The Importance of Quality Tranny Tubes

In conclusion, tranny tubes are essential for the proper functioning of your vehicle’s transmission system. They ensure the smooth transfer of transmission fluid, prevent overheating, and help maintain the longevity of your transmission. Whether you’re replacing worn tubes or installing new ones, it’s essential to choose high-quality materials and perform regular maintenance.

With the right care, your tranny tubes will continue to protect and enhance the performance of your vehicle’s transmission system. So, next time you’re in the market for new tubes, remember the role they play in keeping your car running smoothly, and don’t hesitate to invest in quality products for long-lasting results.

FAQs

1. How can I tell if my transmission fluid tubes are clogged?

- If your vehicle experiences delayed or rough shifting, overheating, or a burning smell from the transmission, it could indicate a clogged fluid tube. Other warning signs include slipping gears, decreased fuel efficiency, or unusual noises like whining or grinding. A clogged tube prevents proper fluid circulation, leading to increased friction and heat. To confirm the issue, a mechanic can inspect the lines and perform a transmission flush to remove blockages and restore proper fluid flow. Regular maintenance can help prevent this issue from occurring.

2. Can I upgrade my transmission fluid tubes for better performance?

- Yes, upgrading to high-performance tubes can enhance your transmission system’s durability and efficiency. Performance-focused tubes, such as braided stainless steel or reinforced rubber lines, offer better resistance to heat, pressure, and wear. These upgrades are especially beneficial for high-performance, heavy-duty, or off-road vehicles, where standard tubes may wear out faster. When upgrading, ensure the new tubes are compatible with your vehicle’s transmission system and provide proper fluid flow without restrictions. Consulting a professional before installation is advisable.

3. Are aftermarket transmission fluid tubes better than OEM ones?

- Aftermarket transmission tubes can be a good option if you’re looking for improved durability or performance. Many aftermarket brands offer reinforced materials and advanced designs that resist corrosion and high temperatures better than some OEM options. However, OEM (Original Equipment Manufacturer) tubes are specifically designed for your vehicle’s transmission system, ensuring a perfect fit and compatibility. If you prefer reliability and factory specifications, sticking with OEM is recommended. If you want enhanced performance, an aftermarket upgrade might be worth considering.

4. What happens if transmission fluid tubes are too long or too short?

- Using improperly sized transmission fluid tubes can lead to serious issues. If the tubes are too long, they may bend, kink, or develop weak points that restrict fluid flow. This can cause pressure buildup, leading to inefficient cooling and potential transmission overheating. On the other hand, if the tubes are too short, they may be under excessive tension, increasing the risk of cracking, leaks, or detachment under high pressure. Always measure and install the correct tube length to ensure optimal fluid circulation, transmission cooling, and overall performance.

5. Can I replace transmission fluid tubes myself, or should I hire a professional?

- Replacing transmission fluid tubes can be a DIY job if you have the right tools and experience working with automotive systems. The process typically involves locating the old tubes, draining the transmission fluid, removing the old tubes, installing new ones, and refilling the transmission fluid. However, improper installation can lead to leaks, pressure loss, and damage to the transmission. If you’re unsure or lack mechanical experience, hiring a professional is the best way to ensure proper fitment, secure connections, and leak-free operation. A professional can also perform a system flush and check for any additional issues during installation.

Learn about InfluncersGoneWild